Contents:

With a laser engraving machine, it is possible to produce custom-made stamps and seals. This equipment is fast and precise ensuring cutting out the smallest patterns.

The first thing that Wattsan experts recommend paying attention to is what material is planned to be processed. Seals are made of special 2-3 mm thick rubber. It should be soft enough for the printing to be as detailed as possible. For stamps, thicker material is chosen.

The second important criteria to be taken into account when choosing a laser engraver is the volume of production per day.

Selecting a model for single-unit and mass production of seals.

Depending on the model, Wattsan machines are equipped differently. Thus, the Wattsan 0203 micro comes with roller guides. A ball touches a guide rail only at one point, which explains relatively low travel speed of the working table and not very high performance. The Wattsan 0503 is equipped with linear guide rails, and its travel speed and ability to withstand heavy loads is higher.

If your task is to produce a small number of items per day, then the Wattsan 0203 is the most suitable option for you. This equipment provides high quality results and is quite cheap. It is one of the most budget-friendly models on the modern market that is characterized by an ideal ratio of price and functions.

The model is designed for home use or small workshops. The 200×300 mm (7.87×11.8 inches) working area size allows working with workpieces of A5 (148×210 mm / 5.83×8.27 inches) format. The machine is easy to adjust, and you do not need special training to operate it. Positioning accuracy is 0.05 mm.

In case of mass production of seals and stamps, we recommend to look at the laser engraver Wattsan 0503. The main difference from the previous model lies in professional kinematics. The machine is designed for continuous operation due to 3-phase stepper motors in combination with linear guides. These units are included in the basic complete set of the model.

Like many other machines of the brand, the Wattsan 0203 and the Wattsan 0503 are universal equipment that can be used for both engraving and cutting. Thus, even if the main task of the owner is to engrave, it can also be used for laser cutting, if necessary.

Mass production

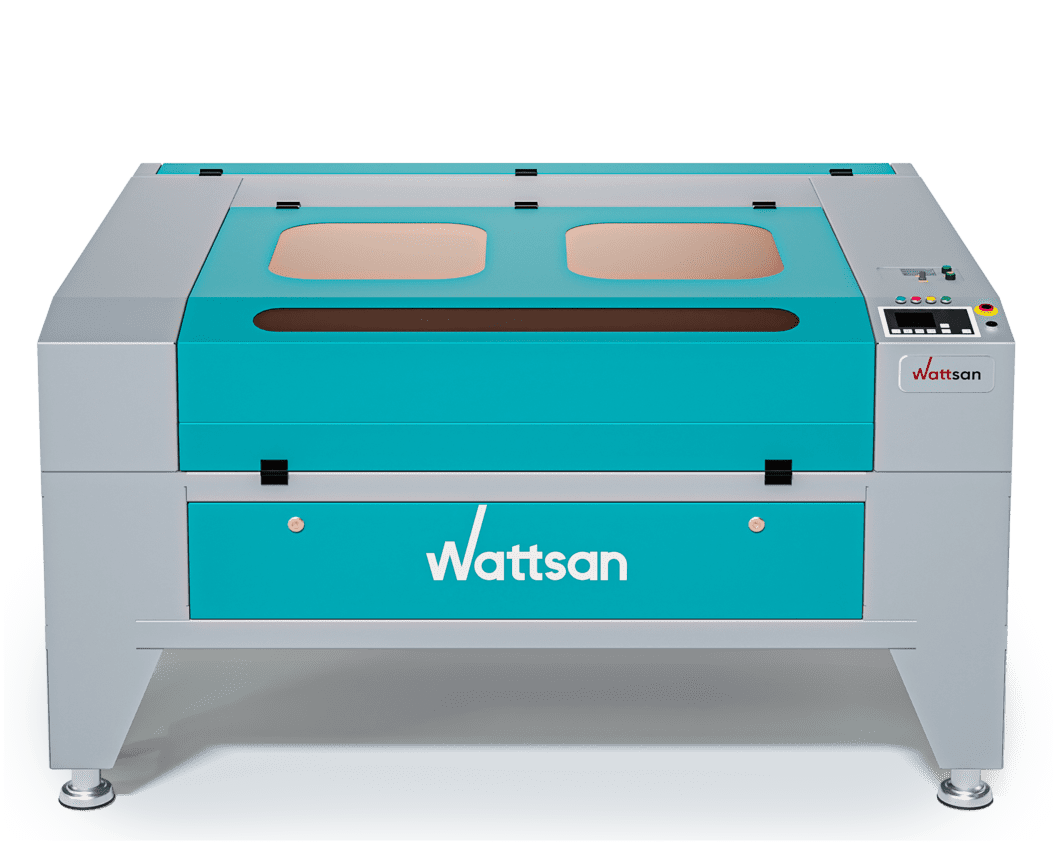

For mass production, one will need a laser machine with an even higher capacity. The Wattsan 1290 Duos is a quite good option.

The main feature of the machine is 2 laser heads that work synchronously and symmetrically. This means that the machine is capable of machining two workpieces at the same time. Thus, production speed is automatically doubled. Note, that the same layout is required for both workpieces. The working area is divided into two parts with one workpiece being machined in each of the parts.

Laser engraving machines for stamp production

As it was already mentioned, thicker rubber is used for stamps. This means that the engraving depth is greater. Thus, the power of the laser tube should be higher than that of the one used for producing seals. Another important point is that stamps are engraved in several runs. This should be noticed when choosing a laser engraving machine.

How to improve engraving quality?

When machining rubber items, you should take into account a number of peculiarities of processing this particular material.

- Preparing the layout in mirror image. For this, there is a Horz Mirror button in the RdWorks software of the machine.

- Single-directional engraving. This function is started using the X_urilateralism button in the control program. In this case, a laser head moves only in one direction, which also improves the quality of the result. The effect is achieved by reducing impact force on the workpiece and the number of touches of the laser beam. This allows you to work with the soft texture of rubber without damaging it.

Top laser engraving machines for manufacturing stamps and seals

In addition to machining rubber and stamps, these machines are perfect for engraving and cutting:

plywood and wood;

acrylic;

plastic;

textile;

paper;

leather;

stone;

glass and much more.

Wattsan 0203 micro

| Work area | 200 x 300 mm |

| Tube power | 40 W |

| Max engraving speed | 700 mm |

| Dimensions | 810x500x265 mm |

It is a compact CO2 laser machine that can be placed on a usual table. Dimensions 810x500x260 mm (31.89×19.68×10.23 inches); working area 200×300 mm (7.87×11.81 inches); weight 28 kg. The power of the laser tube is 40 W. The machine is powered by a 220V power supply. It is suitable for single-item or small-scale production of stamps and seals and for hobby.

Wattsan 0503

| Work area | 500 x 300 mm |

| Tube power | 60 W |

| Max engraving speed | 700 mm |

| Dimensions | 1040x650x575 mm |

A machine with a working area of 500×300 mm (19.68×11.81 inches) can be used for processing different materials including rubber. High accuracy and rigidity of the machine are provided by frame design and 2.9 mm (0.11 inch) thick body. The equipment comes with 3-phase stepper motors and ¼ belt gearboxes ensuring high image fidelity. The machine is intended for serial production.

Wattsan 6040 ST

| Work area | 600 x 400 mm |

| Tube power | 80-90 W |

| Max engraving speed | 500 mm |

| Dimensions | 1165x765x600 mm |

A model with a powerful laser tube (80-90 W) and a working area of 600×400 mm (23.62×15.75 inches). It can machine large volumes of materials in a short time due to the through table function. Frame design and 3-phase steppers eliminate vibrations during operation and ensure high precision. The Fotek inductive sensors prevent collision of gantry elements.

Wattsan 6090 LT

| Work area | 900 x 600 mm |

| Tube power | 80-90 W |

| Max engraving speed | 700 mm |

| Dimensions | 1490x1030x670 mm + 315 mm (if on its wheels) |

The power of a laser tube is 80-90 W, which allows processing solid materials. As the previous model, it is also equipped with a through table and can machine materials of any length. The machine comes with a lifting table that can withstand loads up to 70 kg.

Wattsan 1290 LT

| Work area | 1200 x 900 mm |

| Tube power | 100-120 W |

| Max engraving speed | 700 mm |

| Dimensions | 1790x1410x670 mm + 315 mm (if on its wheels) |

It is one the most powerful Wattsan laser cutting and engraving machines. The power of the laser tube is 100-120 W; the working area size is 1200×900 mm (47.24×35.43 inches). The through-cut function is also available. The machine is equipped with an asynchronous engine that is designed for processing workpieces weighing up to 80 kg.

Conclusion

The correctly selected equipment provides high quality of the final products and desirable performance and can increase the profitability of your business. Hopefully, this article helped to answer some of your questions. For more details, you can always contact Wattsan managers by email or phone.