Contents:

This article aims to provide readers with an understanding of acrylic, including its qualities, types, and applications, as well as the optimal processing method.

Thus, plexiglass, often known as acrylic, is a transparent thermoplastic resin. It offers several benefits. Here are some of them:

- Impact resistant, less fragile than any glass;

- No optical distortion;

- UV-resistant;

- Moisture-resistant;

- Environmentally friendly;

- Soundproof;

- Lightweight enough.

In general, acrylic’s used for a lot of things in various business spheres. For example, in marketing, construction, medicine, engineering: stands, signs, plates, partitions, decorative and lighting elements, details of finishing, flasks, test tubes, greenhouses, verandas, components of prostheses, lenses, windows in aircraft, water & land transport, accessories, etc. Generally speaking, there are plenty of opportunities to start a high-income, long-term business processing acrylic. The most important thing is to select the appropriate plexiglass type & high-quality tools, which we can assist you with!

Consequently, it’s crucial to take the following aspects into account while selecting the material:

- Type;

- Thickness;

- Transparency;

- Colour;

- Depth of engraving;

- Budget.

Now, let’s move from the selection criteria directly to the varieties of organic glass.

Acrylic is distinguished according to the following parameters.

- Method of production:

- Molded:

- High degree of transparency;

- Constant thickness, i.e. always stable, without deviations;

- Minimal internal stress;

- Perfect for deep, accurate engraving, intricate designs, and products that need to have their edges polished when it comes to laser cutting and engraving;

- Extruded:

- Thinner than cast acrylic;

- Impact-resistant;

- Large colour selection;

- Appropriate for items (signs, displays, architectural models) where clarity is not as critical;

- Usually less costly than acrylic cast.

- Molded:

- Gage:

- Thin — 1-3 mm — for exquisite engravings and patterns;

- Medium — 4-6 mm — for various applications;

- Thick — 8 mm or more — to create more durable and long-lasting products.

- Transparency:

- Transparent: when visibility or light transmission is important;

- Translucent: transmits light while diffusing it — creates a soft glow (e.g. decorative, lighting things);

- Opaque: blocks light (e.g. signage, displays, decorative items).

Why are you unable to simply take up any acrylic and stop there? It’s easy — you’ll achieve the finest outcomes if you select the appropriate material for your purposes. Picking the incorrect one could cause it to burn, melt, or crack — it’s not exactly the desired outcome, is it?

Additionally, the decision you make should depend on the tools you’ll be utilising as well as whether you plan to cut or engrave. Keep in mind that extruded acrylic works better for cutting and cast acrylic is better for engraving.

Which Tools Work Best For Acrylic?

A metal hacksaw can be used to cut plexiglass, although this method is best suited for small-scale tasks; otherwise, it will take a considerable amount of time to cut the material by hand.

The notion of utilising an angle grinder and jigsaw better be rejected because, in addition to melting quickly, acrylic is a fairly hard material. Thus, microcracks in the material may form during cutting, which could spread and ultimately destroy the product.

Furthermore, engraving with the aforementioned instruments is extremely challenging or perhaps unfeasible.

You might think about using a milling machine to cut and engrave acrylic. There are benefits and drawbacks to it, which we shall discuss in another article.

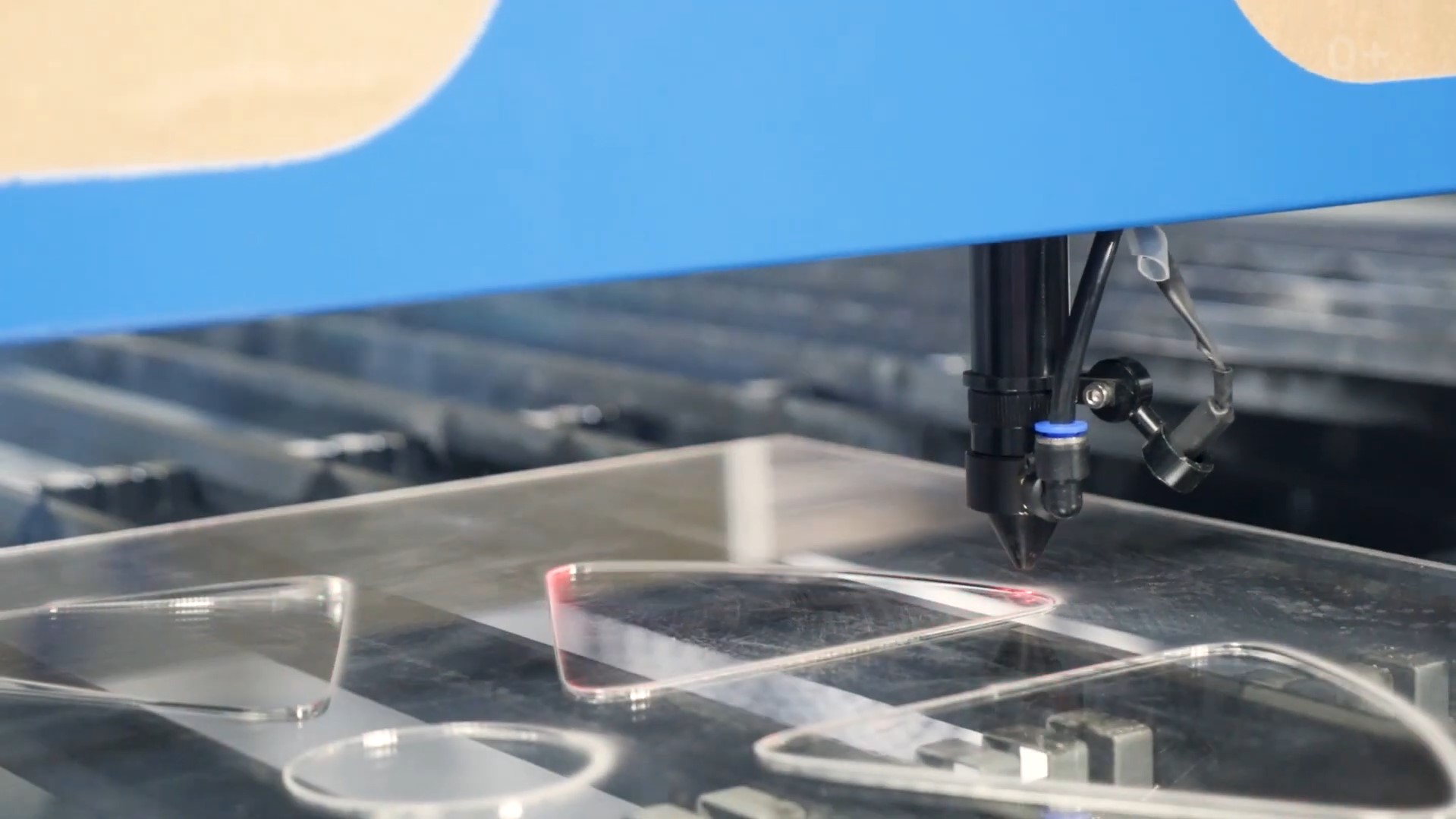

Now, let’s discuss the CO2 laser machine in greater detail. We can use the acrylic laser cutting equipment to make our stuff. In addition, it is capable of processing a wide range of plastics, metal, glass, paper, leather, and other materials. This implies you won’t have to waste time or money looking for, choosing, and purchasing new equipment.

Additional benefits of the CO2 laser include:

- Variety in application; precision and accuracy => saves material and lessens the need for post-processing => boosts production and lowers expenses;

- Rapidity and effectiveness;

- Software and interface that are easy to use.

Among the drawbacks are:

A laser machine’s primary drawback is that it can only engrave or cut through material; unlike a router, it cannot ‘strip’ part of the material to the necessary depth. Milling machines are capable of multi-level processing.

However, you cannot simply turn on the machine and go grab a coffee since cutting acrylic with a laser can quickly ignite the material. Instead, the process must be carefully regulated.

So, the CO2 laser’s almost universal.

How Should I Pick An Acrylic Laser Cutter?

Now that the benefits and drawbacks of the CO2 laser have been established, let’s move on to the technical details. How should one decide? What should I look out for when purchasing? How not to overpay for unnecessary functions?

We advise to concentrate on laser power, bed, chiller, exhaust system, warranty and support of the manufacturer or distributor.

Let’s dissect it more thoroughly.

Work area

Models can have a working area of 200×300 mm to 2000×3000 mm. Make a rough decision based on the size of your upcoming merchandise. If you’re still unsure about what to make, go with the 600×400 mm or 600×900 mm average size.

Laser tube

It establishes the capacity to trim the available thickness efficiently. The laser tube’s power should increase with acrylic thickness. Generally, the idea is as follows: 10 watts of power for every 1 mm of acrylic. Of course, a 60-watt tube can theoretically be used to cut 12 mm acrylic, but the process will be quite sluggish and the outcome would not be ideal.

Work speed

The following is the basic idea behind speed selection: engrave at a high speed while cutting acrylic at a low one. In any event, though, we recommend that you test your selected settings on a prototype first and make any required adjustments. This is because cutting a large batch of identical goods right away runs the danger of destroying the material and turning everything into a defect.

Lens

Lower the lens’s blowing to a minimum—for example, half of the atmosphere—to avoid poor-quality plexiglass cutting, which will result in a rough, rather than a mirror-like edge.

The least amount of pressure is recommended while cutting acrylic. Using a longer nozzle is also advised.

Air is not only superfluous, but detrimental while cutting this material; it’s merely required to keep soot from adhering to the lens; even at the lowest pressure, this is adequate.

When contour engraving, however, the blower should be turned off completely. Additionally, after the work is done, the lens should be wiped and cleaned because silt can build up and cause it to shatter easily.

Chilling system

A chiller is necessary because the laser tube needs to be constantly cooled to avoid overheating. If your tube is less than 60 watts, use a CW-3000 chiller; if it is more powerful, use the recommended Freon-cooled chillers, the CW-5000 and higher.

Exhaust system

It can be risky even with an exhaust system, but a good one will reduce the chance of a fire. Moreover, in its absence, gases that accumulate during the cutting process may explode.

Additionally, organic glass fumes can be very dangerous, so you should purchase an extraction system, keep the machine cover closed, and open the area where it is located.

We recommend that you look into the Fume Extractor.

Warranty and support

Choose a manufacturer or supplier that offers a warranty and provides prompt support for servicing and repairing the equipment you buy.

At Wattsan, for example, we not only have this, but also provide customer training after the machine is purchased. Even if your laser tube gets damaged in transit, we’ll send you a new one absolutely free of charge!

Which Wattsan Acrylic Laser Cutting Machine Is Appropriate?

Now that you know the requirements for selecting a CO2 laser, let’s examine the particular models available for your business.

Small-Scale Models:

0203 Micro

| Work area | 200 x 300 mm |

| Tube power | 40 W |

| Max engraving speed | 700 mm |

| Dimensions | 810x500x265 mm |

This small benchtop device’s more suited for enthusiasts than for industrial manufacturing.

Its working area measures 200 by 300 mm, and its 40 W laser tube is intended to last for about 1500 hours.

Intended to cut materials with a maximum thickness of 5–6 mm.

0503

| Work area | 500 x 300 mm |

| Tube power | 60 W |

| Max engraving speed | 700 mm |

| Dimensions | 1040x650x575 mm |

The desktop model aimed at amateurs with an emphasis on versatility.

Its 500×300 mm work area and 60 W laser tube allow it to cut acrylic up to 8–9 mm thick.

This acrylic engraving machine can process endless lengths of material thanks to its foldable front wall and elevating work table.

Medium-Scaled Models:

6040 ST

| Work area | 600 x 400 mm |

| Tube power | 80-90 W |

| Max engraving speed | 500 mm |

| Dimensions | 1165x765x600 mm |

- Intended for mass and medium production.

- Roll and sheet materials can be processed with its through-cutting table.

- It offers a 600×400 mm work space with an 80 W laser tube that can cut through materials up to 12 mm thick.

- It can be adjusted; for example, the power of the laser tube can be raised. Buying a cooler is advised for best results.

6090

| Work area | 900 x 600 mm |

| Tube power | 80-90 W |

| Max engraving speed | 700 mm |

| Dimensions | 1030x1490x670 mm + 315 mm (if on its wheels) |

- A 900 x 600 mm working surface with a laser tube rated for 80–95 W.

- The acrylic laser cutting machine’s fitted with a through table that can handle materials in the roll and sheet form.

- The table can process materials with non-standard sizes because of its 16 cm lowering depth.

- The table can have a mechanism for raising and lowering it if needed.

- Apart from acrylic, it is also capable of processing non-metallic materials like plywood, wood, veneer, rubber, leather, and textiles.

Large-Scale Models:

1290 ST

| Work area | 1200 x 900 mm |

| Tube power | 100-120 W |

| Max engraving speed | 700 mm |

| Dimensions | 1790x1410x670 mm + 315 mm (if on its wheels) |

- The 1290 ST intended for mass production.

- Working area: 1200 x 900 mm; up to 16 cm automatic lowering possible.

- It’s fitted with a 100–120 W laser tube, though a stronger one can be added if needed.

- Comes fully equipped with an air compressor, controller, and extractor hood for the Ruida control system.

1610 LT

| Work area | 1600 x 1000 mm |

| Tube power | 100-120 W |

| Max engraving speed | 700 mm |

| Dimensions | 1505x2200x670 + 315 mm (if on its wheels) |

- Wide format device for large-scale manufacturing.

- The power of a laser tube is 100–130 W.

- The work surface measures 1600 by 1000 mm.

- You can utilise any length of material with the through table of the acrylic laser cutter.

- Accuracy of positioning is 0.01 mm.

- Utilises non-metallic materials such as plywood, stone, wood, and plexiglass.

2030 Flat Bed

| Work area | 3000 x 2000 mm |

| Tube power | 100-120 W |

| Max engraving speed | 500 mm |

| Dimensions | 2400x3750x800 mm |

- This acrylic laser cutting machine’s best option for working with acrylic, because this material is primarily offered in 2000×3000 mm sheets, and the machine’s specifications allow you to use a complete sheet of acrylic.

- for a major industrial company.

- Because of its sheer size, it may not be suitable for beginners or those producing in a small workshop.

- 100–120 W laser tube.

- A maximum of 500 mm/s is the speed.

- Accuracy of positioning 0.03 mm.

- With sheet materials, it functions flawlessly.

Tips & Tricks

Does The Protective Film Need To Be Removed?

If you have a lot of small components to cut or engrave, it is better to remove the protective film before you start working rather than large ones, which can be removed after milling.

To avoid superfluous scratches on the surface, do not remove the film from the side that will come into contact with the blades.

How May White Patina Be Removed From Acrylic After Engraving?

To clean plexiglass, let’s look at the most effective post-processing techniques:

- Acetone: avoid using too much as it may cause the acrylic to melt; also, avoid getting the chemical on the product’s ends as it may cause them to break;

- Soap solution: after applying it to the acrylic’s surface and letting it dry, the material is etched, producing excellent engraving results without scaling.

In conclusion, acrylic is a material that is utilised in a wide range of applications. As a result, plexiglass products are needed in a wide range of sectors. Additionally, companies that specialise in processing acrylic typically have a large clientele, a high volume of orders, and great success. Selecting high-quality equipment, such as an acrylic laser cutting machine, is crucial, and it will put half of the success in your wallet. We also want to remind you that the settings should be adjusted based on the kind of processing, thickness, and kind of acrylic: low speed and high power for cutting, high speed and low power for engraving, minimum blowing for contour engraving, and turning off the blowing for contour engraving.