Contents:

We know that lasers can cut metal, wood, acrylic and leather. But can a laser cut a thin and flammable material like paper? Whatever you want!

But first let’s find out what kind of paper you want to work with. Yes, there are different types and you need to know their characteristics before you start working. Well, there really are many types of this material. Some are easy to work with. Some have additives and impurities in their composition or coating, so that the harmful vapours released when the beam heats up do not enter the operator’s lungs but are carried away, so you need good ventilation. And to cut very thin paper, such as tracing paper, it is necessary to use either relatively low laser power or ultraviolet, or to do it manually.

So what kind of paper and cardboard can be cut? Here’s a list:

- Postcard paper (e.g. scrapbooking);

- Copy paper;

- Art print paper;

- Industrial double-ply paper;

- Construction paper;

- Cartonboard;

- Electrical board;

- Corrugated cartonboard.

Where is laser paper cutting applied?

So, we’ve got the varieties sorted out. What is this material processed for? Which industries need it? What kinds of goods are produced there?

To begin with, a lot of paper cutting — especially cardboard — is needed for packing and printing, for instance, for creating boxes, invites, business cards, postcards, and other items.

The following should be noted in addition to the application fields listed above:

- Crafts and arts: stencils, scrapbooking, festive decorations;

- Publishing: book bindings;

- Advertising and promotional activities: pop-up windows, flyers, booklets;

- Architecture: layouts;

- Electronics: insulating layers;

- Toys: house of cards, paperdolls.

Which tool is ideal for machining?

Basically, with any instrument, paper can be cut, because it doesn’t require much power. But let’s still study the question thoroughly!

Mechanical tools for cutting paper

So, there are the following devices for cutting paper or cardboard.

- Stationery or universal scissors:

- One of the most obvious ways of cutting the material in question, but not the most convenient and fast: at a time they can cut a few sheets of paper, and cardboard — not all of it.

- Knives:

- Modelling — intended for artistic endeavours when neatness and cutting accuracy are crucial; typically used for cutting out figures;

- Circular — chops cardboard and paper nicely, but it struggles, for instance, with filter paper, because it is very thin — 0,15-0,25 mm; this knife is frequently used in construction to drill socket holes.

- Cutting knives:

- Roller / disc / trimmer — fast trimming or cutting of small volumes of documents — up to 15 sheets;

- Sabre — simultaneous cutting of up to 50 sheets of paper;

- Guillotine — a few hundred sheets of paper at a time, several centimetres thick.

The aforementioned tools’ primary functions are repetitive cutting and obtaining circulation products. For instance, using a cutter will result in faster and more efficient work if you need to create 100 identical cardboard boxes. A laser machine is the best option if producing unique or non-unique paper or cardboard items is crucial for your company.

Laser paper cutting machines

- UV;

- Diode;

- CO2:

- flatbed (laser head and mirror system),

- scanner (galvo scanner – guiding beam).

UV is thought to be the best of the aforementioned lasers in terms of cutting paper goods quality. He very quickly performs the most painstaking work even on very thin paper. If you would like to learn more about this type, please contact our managers — they will advise you and, based on your needs, choose either UV laser or some other type.

The scanning carbon dioxide laser is particularly noteworthy amongst carbon dioxide lasers due to its observable superior speed, efficiency, and accuracy over the flatbed laser. However, it falls short of the UV laser in terms of output quality and speed.

We still recommend using a CO2 laser machine when selecting equipment for cutting and engraving cardboard and paper. Why? There are numerous valid explanations.

- First, cost: a laser carbon dioxide CNC machine is far less expensive than an ultraviolet one, while maintaining a high-quality output.

- Best value for money: we recommend against overpaying and opting for CO2 if your company doesn’t need to accomplish anything extremely complicated.

- You won’t have to spend more money on a new machine if you wish to make different products from non-metallic materials because it works with all organic materials.

- Many features: a laser CO2 machine may engrave in addition to cutting, something that isn’t conceivable with a cutter or scissors, for example.

- Non-contact, fast and precise work.

- Cost-effective: very little laser power is required to process paper, so not much electricity is wasted.

Nevertheless, we should not forget about this type of processing disadvantages.

- Naturally, a laser machine is more costly than a pair of scissors or a mechanical cutter.

- It is essential to possess or acquire the knowledge of operating laser equipment.

How should a laser paper cutting machine be selected?

Alright, we now know what kind of equipment to select. However, how can it be done? What information is necessary for you to make an informed decision? Together, let’s sort it out.

It is usually advisable to check the characteristics of these parts when searching for any machine:

- Working field;

- Table;

- Compressor;

- Power of a laser tube;

- Lens;

- Exhaust air system, chiller.

Let’s think about the qualities that our machine should have in order to cut and engrave cardboard and paper.

Working field

We suggest making a decision based on the size of your output. If you are just starting out or own a small business, a tabletop or medium format will suffice – for example, 200*300 mm or 500*400 mm. If your production is large, look for larger tables such as 600*900 mm or 1200*900 mm.

Table

If you plan to process only paper materials, choose a honeycomb table. The table lowering feature won’t be necessary because cardboard, and particularly paper, sheets, are thin and flat.

Compressor

Its primary function is to blow out the focusing lens to prevent soot buildup and overheating, which would cause it to fail soon and require replacement.

The primary requirement for us to work with paper materials is that we select a compressor that has air pressure adjustment capability. Regarding the selection of settings, we offer some suggestions. The compressor pressure should be as low as 0.2–0.5 atmospheres when cutting paper. A greater value — say, two atmospheres — will cause the material to just blow away. You can select approximately 1 atmosphere for cardboard because it is thicker than paper. The pressure conditions should once more be at or below 0.2 atmosphere for etching these materials.

Laser tube

Picking one that is very powerful is not necessary for paper and cardboard; 50 W is plenty. For instance, a straight paper cut works best with a feed rate of 150 mm/s and a power of 15-20 W. It is preferable to adjust the parameters as follows for intricate cutting: 30 mm/s and 10 W. Remember that everything is dependent on your machine and the kind of material you are using, so it is best to make your own decisions by adjusting the feed rate. A healthy mix of low power and high feed rate is necessary for optimal outcomes.

Lens

The lens determines the laser tube power selection, not the product’s thickness that needs to be machined. Short-focus will do, even if you have to cut corrugated cardboard.

Exhaust air system and chiller

You cannot cut corners when it comes to having an extraction system at your workplace because paper and cardboard are readily flammable materials.

Regardless of the type of material processing we perform on the machine, a chiller is required to cool the laser tube.

Additionally, to avoid making a mistake while selecting a laser CO2 CNC machine, get in touch with our Wattsan managers. We’ll assist you in locating the ideal equipment for your requirements.

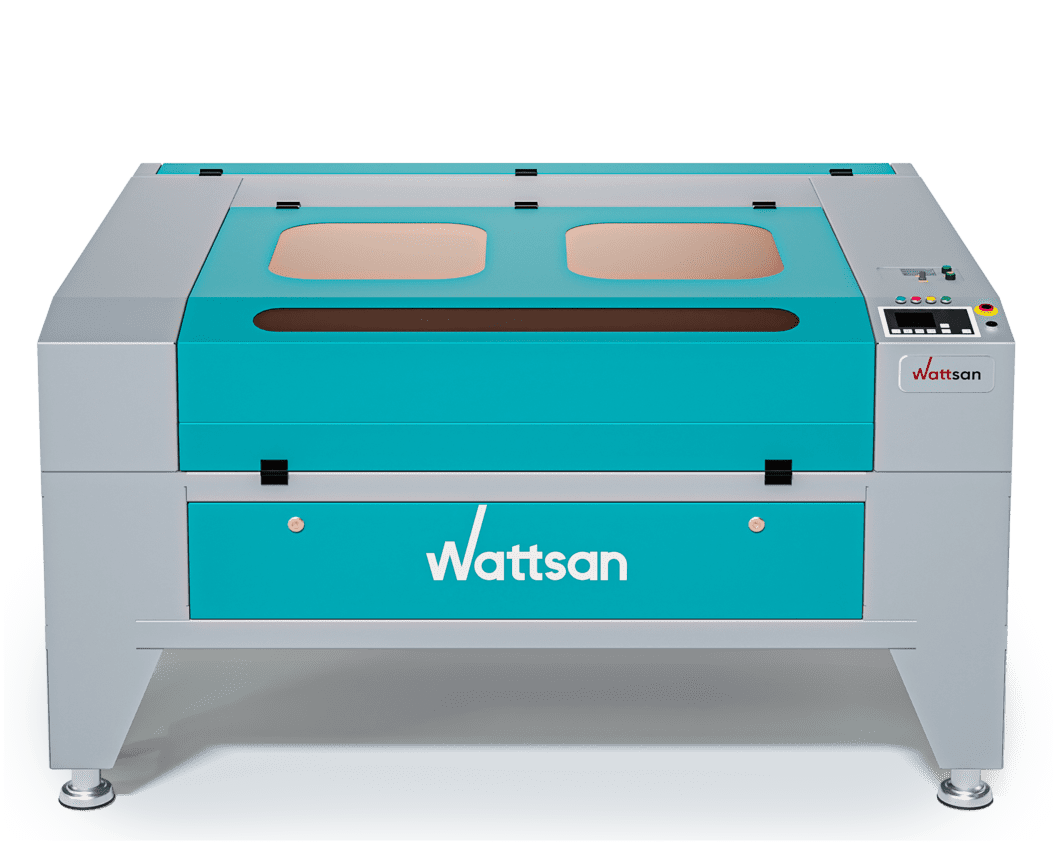

Which Wattsan laser paper cutter ought I to pick?

A large selection of laser machines for paper and cardboard are available from Wattsan. Here’s a quick overview:

0203 micro

| Work area | 200 x 300 mm |

| Tube power | 40 W |

| Max engraving speed | 700 mm |

| Dimensions | 810x500x265 mm |

The machine is quite small and readily fits on a table. This model’s 40 W laser tube and 210*297 mm working field make it ideal for handling small products. The working field is roughly the size of an A4 sheet. A great option for small production or personal use!

0503

| Work area | 500 x 300 mm |

| Tube power | 60 W |

| Max engraving speed | 700 mm |

| Dimensions | 1040x650x575 mm |

The size of the working area here is slightly larger than the A3 format. Because of its medium size, it may not fit on the table. This machine has a 60 W tube, which is suitable for paper materials.

6040 ST

| Work area | 600 x 400 mm |

| Tube power | 80-90 W |

| Max engraving speed | 500 mm |

| Dimensions | 1165x765x600 mm |

This is an advanced model of medium size (600*400 mm), which will suit both hobbyists and medium-sized business owners. It has a fairly powerful 80-90W tube installed. By the way, 6040 ST can process materials up to 8 mm thick, which suits us, as even corrugated cardboard is usually not more than 5 mm thick.

6090 LT

| Work area | 900 x 600 mm |

| Tube power | 80-90 W |

| Max engraving speed | 700 mm |

| Dimensions | 1490x1030x670 mm + 315 mm (if on its wheels) |

At 600 by 900 mm, this machine is already very large, making it appropriate for large-scale production. This model’s 80–90 watt tube is the same as the one used in the previous one. performs admirably with organic materials—exactly what we require.

1290 LT

| Work area | 1200 x 900 mm |

| Tube power | 100-120 W |

| Max engraving speed | 700 mm |

| Dimensions | 1790x1410x670 mm + 315 mm (if on its wheels) |

It is possible to refer to this model as the most potent of this review in every way. The tube is 100–120 W, and the working field is 1200*900 mm. For large-sized items in particular, it is perfect for multi-series production.

Can I design with a laser paper cutting machine?

Undoubtedly, the use of paper has been transformed by laser cutting machines, which offer even more creative and design options for producing one-of-a-kind, expertly crafted things in a flash. The materials can be cut and engraved with a laser cutter. A tedious pattern, image, or inscription cannot be precisely and swiftly cut out by hand. But it’s easy with a laser! Furthermore, if you, of course, establish the proper guidelines for working with paper, the final product’s quality will always be consistently good.

With a laser’s assistance, you can make, for example, unusual pictures, gift boxes, festive decorations, paper lanterns, wedding decor, cards, invitations, 3D models and sculptures, cake sides and many other things. We can’t fail to mention Chinese paper cutting — Jianzhi, popular traditional Chinese art forms.

Therefore, with a laser paper cutting machine, you can create anything precise out of paper or cardboard, and the work will be done quickly and well, ensuring that your idea will seem precisely as it does in the layout. The most essential thing to keep in mind is that you must always establish the proper parameters while working with cardboard and paper. For example, you must use a hood and chiller and set the processing speed to high and the laser tube power to low. You should also use a honeycomb working surface. Enjoy cutting and engraving paper goods with the Wattsan paper laser cutting machine — it’s a dependable and helpful tool!